Corporate

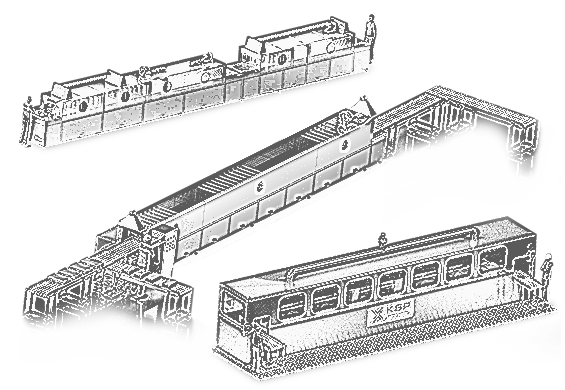

KSP Machine

KSP has been serving the engine maintenance industry since 1998 with its machinery and equipment. Throughout the years we serve, we have become a leading company in the international market with our product and service quality. We have adopted ourselves as a principle to continuously develop new products according to the requirements of the market and to develop our products and services according to the needs of our customers.

Details

Special Products